ifm electronic has introduced the SM Foodmag, a line of magnetic-inductive flow meters designed to deliver precise flow measurement tailored to the food and beverage sector. Built to uphold stringent hygiene requirements while enduring demanding process conditions, the SM Foodmag offers a versatile solution for everything from small dosing lines to large supply pipelines.

The SM Foodmag eliminates blind spots during production by leveraging IO-Link technology to provide comprehensive process data. Unlike traditional sensors that simply monitor flow, this innovative device simultaneously measures four critical process parameters: volumetric flow, total volume, temperature, and conductivity. This multi-parameter capability enables manufacturers to reduce the number of measurement points in their systems while gaining more detailed insights into their operations.

Designed specifically for the food industry, the sensor is suitable for a wide range of media, including milk, cream, beer, fruit juices, and water. It is fully compatible with CIP (Cleaning in Place) and SIP (Sterilise in Place) processes, featuring a durable stainless-steel construction and the ability to permanently withstand media temperatures of up to 150°C. The integrated conductivity measurement further boosts efficiency by detecting phase changes in the media, enabling optimised cleaning cycles and minimised waste.

A standout feature of the SM Foodmag is its modular flexibility. The system comprises a measuring pipe, seal, and process adapter, making it fully customisable to suit specific installation needs. Covering a variety of line sizes, the sensor can be easily retrofitted into existing systems thanks to standard installation dimensions and a variety of adapters, including weld-in, clamp, or DIN connections.

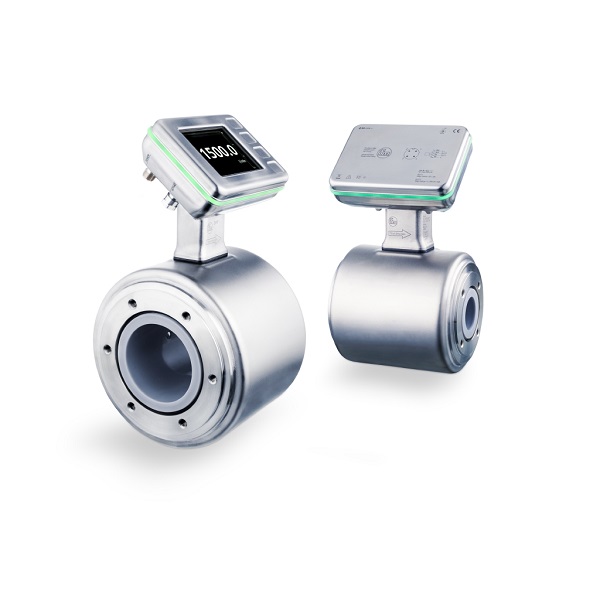

Operators will appreciate its user-friendly design. The device is equipped with a fully graphic, and rotatable, 3.5″ display and a 360° LED status ring, offering instant visual feedback on the sensor’s operational status. A guided installation wizard and app-based menu structure make configuration both quick and intuitive. For seamless digital integration, the SM Foodmag uses IO-Link to transmit data reliably to controllers and IT systems, ensuring full transparency and enabling Industry 4.0 implementation.

The robust construction also addresses common mechanical challenges. By separating the measuring pipe from the electronics and incorporating a slim, lightweight housing, the SM Foodmag significantly reduces the risk of failure caused by vibration and shock. A standard M12 connector ensures a watertight, error-free connection, eliminating the need for the complex terminal chambers often associated with traditional flow meters.