The latest update to KIT®, the intelligent tool and equipment management platform, introduces a more efficient and adaptable way to perform and record audits for customers across aerospace, automotive and food & drink manufacturing. In sectors where speed, accuracy and accountability are essential, teams need systems that evolve with their operational needs.

This release introduces a new audit method based on confirming the presence of items. Users simply scan what is physically in front of them; anything not scanned is automatically flagged as missing. This approach is ideal for uncontrolled environments such as tool cupboards or rooms of jigs and fixtures that have traditionally been difficult to audit.

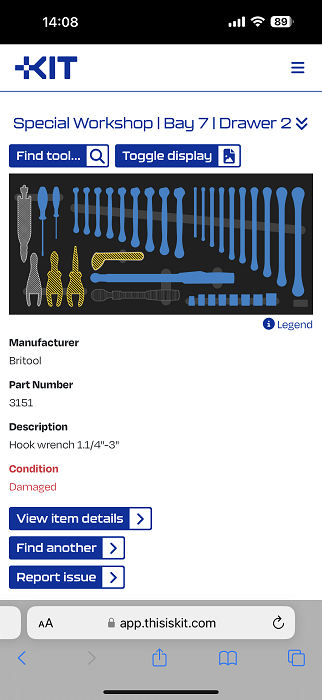

With support for scanners and mobile devices, users can quickly verify tools on shelves, transforming previously “too difficult” locations into fast, manageable audit tasks and delivering full visibility within a single system.

The update enables audits across entire Location Groups, reducing the steps and time taken to audit multiple Locations. Now, Users can simply select the Location Group they wish to audit and begin a new automated workflow that steps through the audits for all Locations in that Group, enabling whole tool cabinets or even the tooling in an entire production cell to be completed in one visit, rather than having to scan and audit each tool drawer Location separately. Audits can now be paused to reflect shift patterns, staff absence or periods where certain tools are not needed.

Audit policies can also be limited to specific days, ensuring weekend‑only or non‑operational days are excluded automatically. These improvements streamline audit workflows and ensure reporting aligns with real working practices.

The handling of Missing Items has been enhanced as well. Items can now be marked as found without re‑auditing their location, reducing time and administrative overhead.

“We’re incredibly proud of this release. It introduces real versatility to running tool audits. By rethinking the audit model with our customers, we’ve delivered a more flexible and practical approach that supports manufacturers’ digital transformation efforts.” Paul Mazaher, Managing Director of KIT, added: “Our goal is simple: provide fast, intuitive solutions that fit how teams work. When tool control is easy to use, adoption increases and manufacturers see real gains in efficiency, control and ownership.”