Power and performance

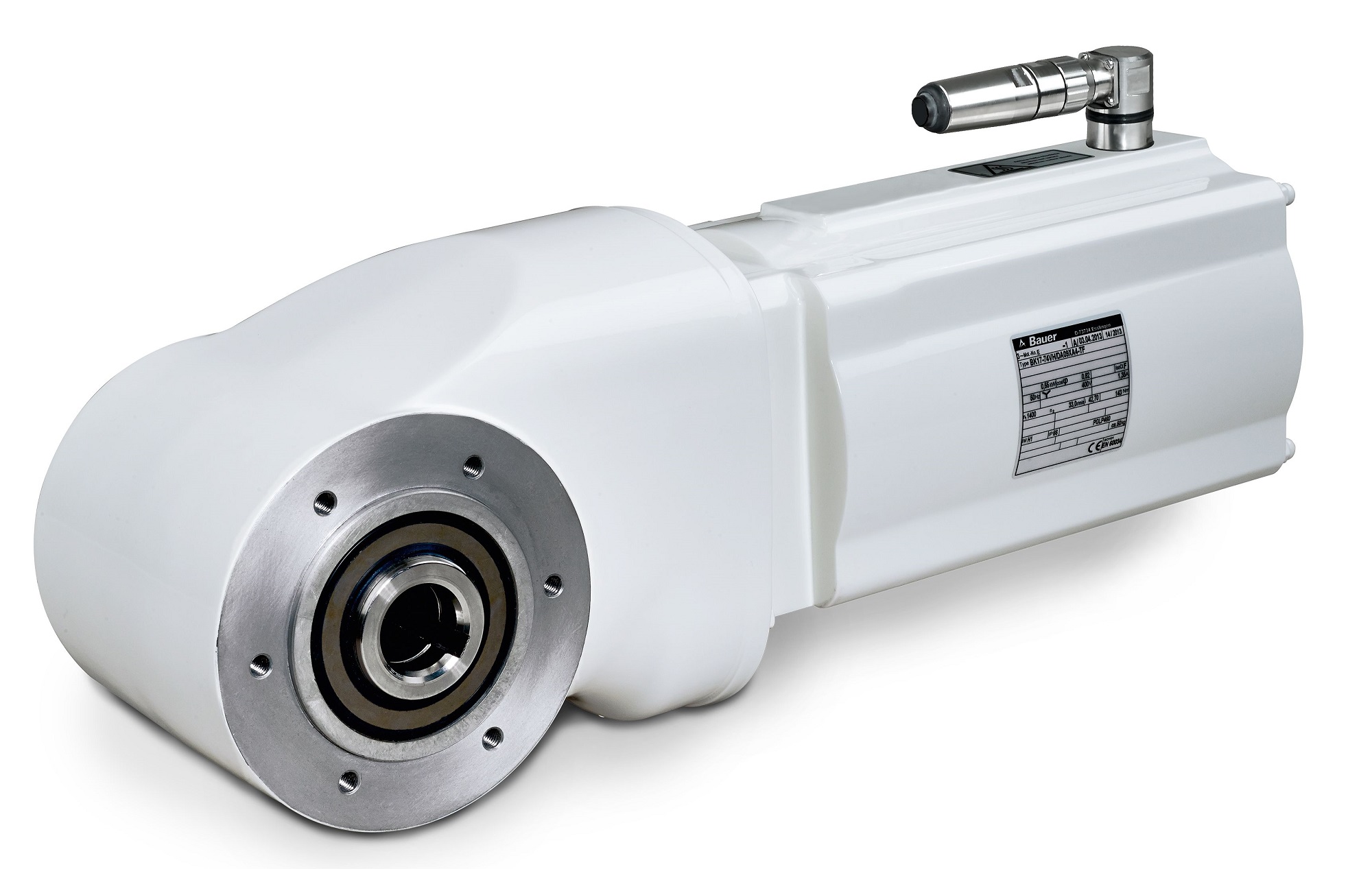

At the heart of many high-performance conveyor systems found in bottling lines are Bauer Gear Motor™ solutions. These compact, efficient gear motors are known for their durability and resistance to harsh washdown environments, a critical requirement in beverage processing. Boston Gear™ complements this offering with robust enclosed gear drives and motion control components, ensuring smooth, dependable operation throughout the plant.

Smart automation

Kollmorgen™ direct drive and washdown-ready servo motion systems enable ultra-fast bottling and capping with pinpoint accuracy and minimal waste. By eliminating mechanical backlash and enabling real-time adjustments, Kollmorgen technology ensures consistent fill levels, reduces product giveaway, and keeps manufacturers compliant with labelling regulations. And with stainless steel and anodized aluminium motors built for rapid, thorough washdown, lines stay clean, safe, and productive. Kollmorgen’s servo motors and drives are also ideal for robotic arms performing repetitive tasks such as case packaging and shrink wrapping, boosting throughput and reducing human error.

Bearing the load

In high-speed bottling operations, dependable bearing systems are essential. Sealmaster™ bearings provide superior sealing and corrosion resistance, extending service life in wet or acidic environments often found in drinks production. For linear motion applications, precision linear actuators and guides from Thomson™ ensure accurate, repeatable movement, helping manufacturers achieve consistent fill levels and label alignment.

Stopping power

Safety and control are paramount in bottling lines, particularly where frequent start-stop cycles are required. Regal Rexnord’s advanced brake systems, including electromagnetic clutches and brakes, offer fast response times and minimal maintenance. These systems are integral to conveyor indexing, cap placement, and labeling processes, helping maintain productivity while safeguarding both equipment and personnel.

The Regal Rexnord advantage

By leveraging the full family of Regal Rexnord brands, OEMs and end users can simplify their procurement, logistics, and maintenance processes. Instead of sourcing from multiple vendors, equipment manufacturers can work with one trusted supplier for mechanical power transmission, motion control, and automation needs. This not only streamlines system design and integration but also ensures component compatibility and coordinated support throughout the product lifecycle.

Whether building a new bottling line or upgrading existing equipment, Regal Rexnord delivers complete, factory-optimized powertrain solutions tailored to the unique demands of the beverage industry. From the first gear motor to the final robotic palletizer, every component is backed by engineering expertise, global support, and a commitment to keeping your line moving.

Regal Rexnord: Powering the future of beverage manufacturing.