By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Products such as mechanically separated meat (MSM) and meat emulsions are commonly used in a wide range of products including sausages, chicken nuggets, patties and some minced meats. While different meat sources and products will have different processing and cooking requirements, it is important that the methods chosen to minimise the energy use involved, saving money and reducing greenhouse gas emissions.

Meat emulsions, slurries and reformed meat products have been used around the world since the early 1970s. Around the world there are strict rules, both about the raw materials used for the production of MSM, but also how it is processed and labelled. Similar cooking, handling and cooling methods are also used for other food products, such as ground (minced) meat and soups, and these products can also benefit from the same approach to choosing cooking systems.

The European Food Safety Authority (EFSA) advises that, ‘Microbiological and chemical hazards associated with mechanically separated meat derived from poultry and swine are similar to those related to non-mechanically separated meat (fresh meat, minced meat or meat preparations). However, the risk of microbial growth increases with the use of high-pressure production processes.’ In addition, ‘High pressure mechanically separated meat must be immediately frozen and can only be used in cooked products.’

These products are often cooked in batches prior to final product formation, often using large steam-powered kettles or pressure vessels. Some companies processing large volumes of product may have ten or more vessels in various states of operation at one time. This is because, while these vessels are an effective method of cooking and pasteurising a range of products including MSM, they are limited in their capacity because it is important that the product is cooked through thoroughly. Because each vessel must be heated from scratch for every new batch of product, and the heat used is then lost when the vessel is emptied, this is an incredibly inefficient method of cooking such products.

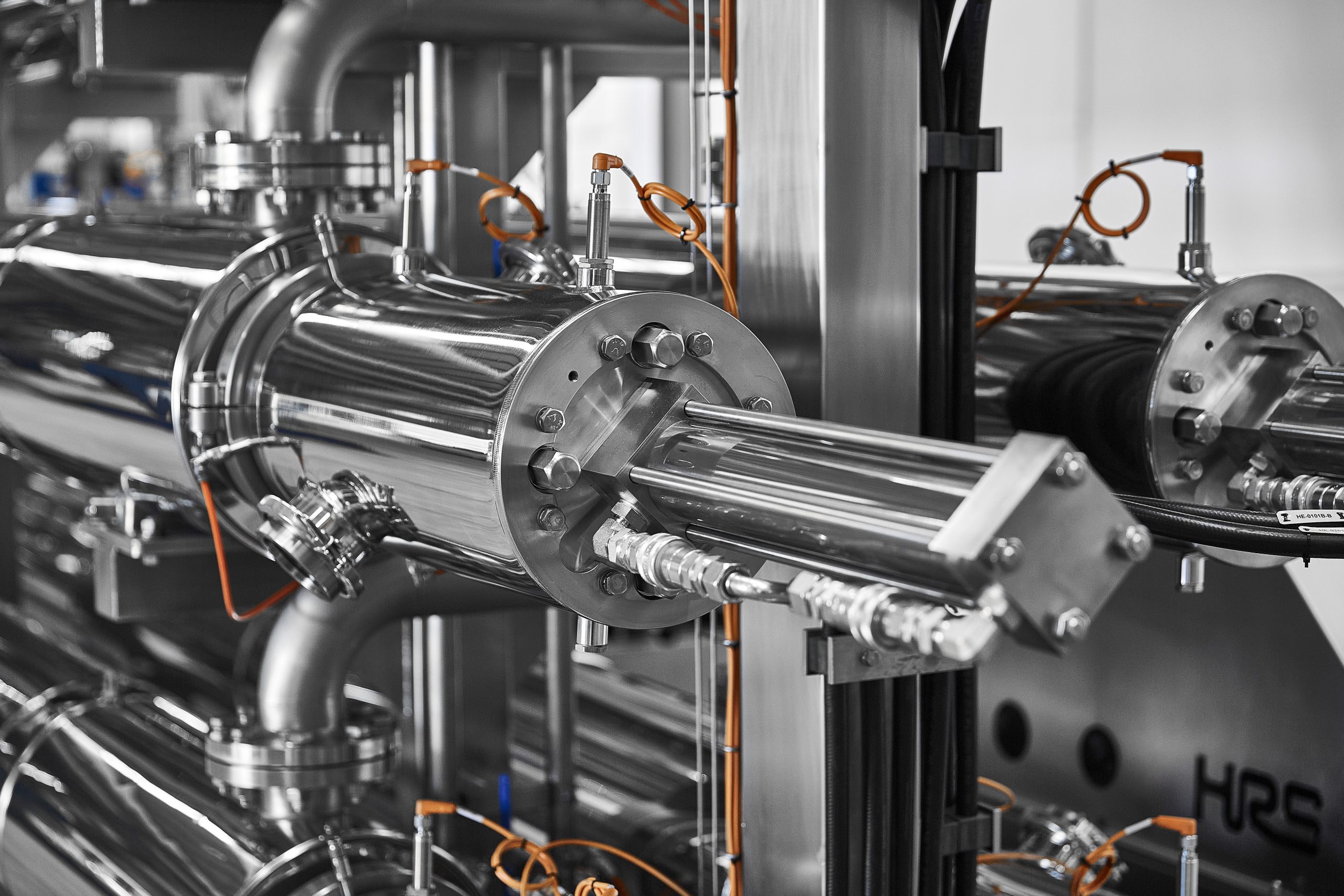

A much more energy efficient method is to cook a continuous stream of product using a scraped surface heat exchanger such as the HRS R Series or Unicus Series. The HRS R Series uses a rotating action to scrape the tube surface and a helix to ‘push’ material through the heat exchanger, ensuring thorough mixing and heat distribution. It provides an economic solution for situations where product mixing is a benefit in processing, or where physical integrity is less important than heat transfer. For example, it is ideal for MSM, meat emulsions and co-products (such as materials which are destined for the pet food market).

In some situations, the robust mixing action of the R Series can damage the product. For example, some minced and ground meat products, or products containing definite pieces or product. In this case the HRS Unicus Series is preferred. This patented design uses as reciprocal action to prevent fouling of the heat exchanger by the product and to ensure thorough heating of the product to the required temperature. Importantly, once the unit has reached the required temperature, the heating medium is only required to maintain the temperature as the heat is not lost between processing batches. This continuous processing saves large amounts of energy compared to a batch approach.

The same is also true of the equally important cooling process, which must be conducted in a timely manner. In fact, this cooling allows for the use of heat generation, where the heat removed by the cooling process is not lost but can be returned to the start to pre-heat the product, so that less energy (for example steam) is required for heating. Further economic savings are also achieved by reducing the need to fill and empty separate cooking vessels, and the fact that cleaning-in-place (CIP) can be performed when required, rather than simply between each (smaller) batch.

HRS have provided clients with continuous processing solutions to replace batch-cooking and cooling systems. One Colorado-based manufacturer of sauces and soups replaced their batch-based system with a continuous process based on a number of HRS products in order to increase their manufacturing capacity to meet increasing demand.

HRS complete systems not only include the HRS R Series and Unicus Series scraped surface heat exchangers for cooking and then cooling the product, but also transfer pumps, balance tanks, other heat exchangers for pre-heating and pre-cooling, and auxiliary equipment such as CIP systems and steam-powered hot water sets. Such systems are designed to have simple intuitive controls and to occupy the smallest possible footprint in order to fit within existing production facilities.