Building upon a 30-year legacy of trust, collaboration, and innovation, SATO and ALTech continue to push the boundaries of print technology. Their most recent achievement, the deployment of the S84/86NX smart print engines, paves the way for an even brighter future.

Rory Horton-Smith, Managing Director of ALTech UK, shares his insights on the impact they have already had on ALTech labelling processes and the future of the partnership.

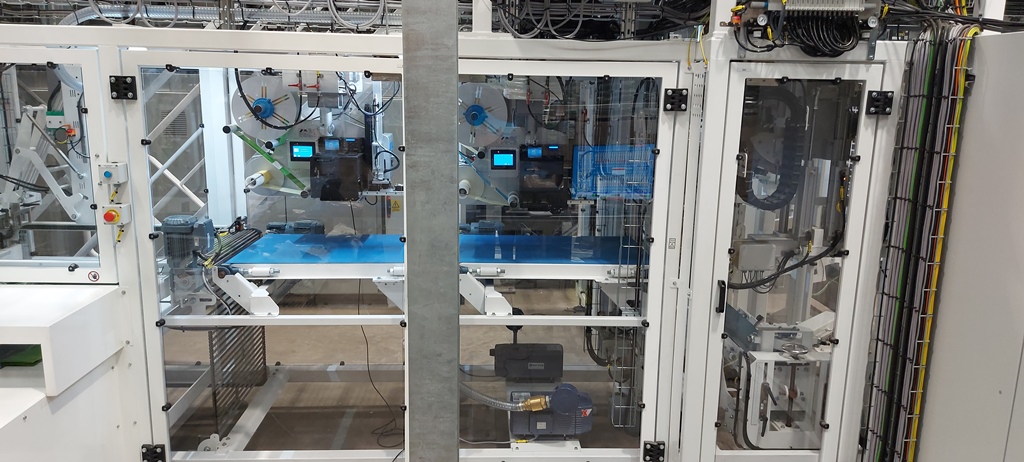

SATO, a global leader in auto-ID and labelling solutions, manufacture the innovative S84/86NX smart print engines, designed for automation and on-site usability. Equipped with Application-Enabled Printing (AEP), they offer enhanced customisation and improved performance in harsh industrial environments. The partnership between SATO and ALTech, spanning over three decades, is testament to the benefits of these ground-breaking print engines in food labelling automation.

Rory Horton-Smith, Managing Director of ALTech UK – the UK subsidiary of ALTech, shares his insights on how SATO’s S84/86NX smart print engines have boosted their operational capacity, highlighting the key role of the AEP functionality: “This additional intelligence provides us with the ability to provide solutions that used to be difficult.” Thanks to AEP, for example, warehouse operators can directly connect to weigh scales, automate weight input and print from programmable logic controllers (PLCs), halving the reprogramming time required.

The SATO print engines have streamlined ALTech’s customers operations, providing reduced labour costs and enhanced operational efficiency. Automating labelling processes has allowed these companies to focus on boosting productivity and saving costs. The autolabelling abilities of the print engine provide enhanced real-time traceability and extra intelligence that breaks new ground. Rory highlights the benefits of real-time updates, saying: “From a traceability perspective, the intelligence of the printer potentially allows recording of the label printed (e.g. to a network file) as well as just printing it, for example” The S84/86NX print engines are designed for demanding industrial environments, resistant to solvents and water and ideal for factories and warehouses where extreme temperatures and varying conditions are the norm. Features like the open cover sensors and stronger hinges and nip rollers add durability, extending the product’s lifespan in the 24/7 ecommerce fulfilment era. With SATO’s preventative maintenance service, SOS, users can remotely monitor the status of their print engines on a single dashboard, eliminating downtime and keeping operations running smoothly. Rory also commends the seamless retrocompatibility of the SATO print engine with existing setups and its emulation. Scope to integrate the new print engines effortlessly makes the transition from older labelling solutions smoother and more efficient.

All of which means the SATO-ALTech partnership continues to flourish, thanks to a shared commitment to innovate and remain ahead of the curve. The SATO S84/86NX smart print engines, with their advanced features and flexibility, have proven invaluable in addressing complex challenges for ALTech and their customers in the food labelling automation industry. As both companies look to the future, they will continue to provide cutting-edge solutions and set the pace in the market, revolutionising food labelling processes and enhancing efficiency in the sector.